A steam surface condenser is a critical component of a power plant. The generating capacity of a power plant is dependent on the performance of the steam surface condenser. Maarky condensers are designed to provide the lowest backpressure which, in turn, maximizes the output from the power plant.

Steam surface condensers are offered for power plants ranging in output from 10 MW to 1000 MW and in the following configurations:

- Cylindrical, Inverted “U”, or Rectangular

- Axial or Down Exhaust

- Single or Multiple-Pressure

- Single or Multiple-Shell

- Divided or Non-Divided Waterbox

- One Pass or Multi-Pass

Each condenser is designed in accordance with the client’s specifications to offer the highest thermal efficiency and structural integrity. The thermal, hydraulic and mechanical aspects of the condenser are designed using state-of-the-art-technology. The design is in accordance with the following codes and standards:

- Heat Exchange Institute (HEI)

- American Society of Mechanical Engineers (ASME)

- Electric Power Research Institute (EPRI)

Each component of the condenser is designed to provide superior performance, simplified fabrication and easy installation. The robust and creative designs offer excellent performance when operated at the design point as well as off design conditions.

Trouble-free performance in turbine bypass operation is of paramount importance in a combined cycle plant. With the steam turbine out of service, the high pressure and high temperature steam discharged from the heat recovery steam generator (HRSG) is directed to a pressure reducing desuperheating (PRD) valve wherein the pressure and temperature of the steam is reduced to desired values. The bypass steam from the PRD valve is admitted directly into the condenser. The above mode of operation is commonly referred to as bypass operation.

Maarky condensers are designed to operate reliably in bypass operation. The range of steam pressures and temperatures admitted into the condenser is carefully established to avoid “wet steam” condition. The bypass headers are designed and strategically located to avoid damage to tubes and condenser internals from impinging steam. Proper interface between the PRD valve supplier, the architect engineer and the condenser designer is of prime importance. The scope of supply for each party is clearly defined to avoid errors due to miscommunication and to ensure reliable operation.

Steam flows in a condenser at normal, startup and transient conditions are complex in nature. These complex thermal, hydraulic, and structural interactions are predicted by using state of the art Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) tools such as FLUENT and ANSYS.

Maarky steam surface condensers are designed and fabricated in the largest possible sections to minimize field erection. All components are match-marked in the factory to ensure proper alignment. Any misalignment is corrected in the factory prior to shipment. Adequate provisions are included to facilitate lifting and maneuvering the sub-assemblies in the field. Accurate alignment and proper lifting arrangements permit erection of the components at the lowest cost and shortest schedule.

Maarky steam surface condensers are designed and fabricated in the largest possible sections to minimize field erection. All components are match-marked in the factory to ensure proper alignment. Any misalignment is corrected in the factory prior to shipment. Adequate provisions are included to facilitate lifting and maneuvering the sub-assemblies in the field. Accurate alignment and proper lifting arrangements permit erection of the components at the lowest cost and shortest schedule.

Optimal performance of a condenser is achieved with the proper design and selection of a wide array of auxiliary systems. The evacuation package is a critical auxiliary item. Continuous evacuation of non-condensable gases is essential for proper condensation of steam in a condenser. Steam jet air ejectors or liquid ring vacuum pump systems are the primary means of evacuating non-condensable gases from a condenser. Another important auxiliary item is the waterbox priming system, which facilitates the flow of the circulating water through the tube side of the condenser in a once-through cooling system. Other auxiliary systems that enhance the performance of the condenser are the condensate pump system, cathodic protection systems, continuous ball cleaning system, pressure reducing desuperheating valves, expansion joints, and a variety of instrumentation.

Maarky offers the following auxiliary items along with the steam surface condenser:

- Steam Jet Air Ejector System

- Liquid Ring Vacuum Pump Systems

- Waterbox Priming Systems

- Continuous Ball Tube Cleaning Systems

- Condensate Pump Systems

- Waterbox Cathodic Protection Systems

- Deaeration Systems (for large quantities of makeup water)

- Condenser to Turbine Expansion Joints

The auxiliary systems are carefully designed to supplement the performance of the condenser at all modes of operation and are procured from suppliers with proven record of quality and reliability.

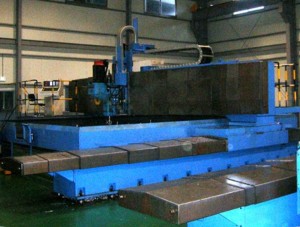

Configurations of Condenser Option offered:

[portfolio_slideshow]

All of the above-noted condensers are equipped with two tube passes and divided water boxes. The condenser can be designed with the following features:

- One, two, three or four passes

- Divided or non-divided water boxes

- Top steam inlet or Axial steam inlet

- Revise location and orientation of circulating water inlet and outlet nozzles