Regenerative heating of feedwater is essential to enhancing the efficiency of a power cycle. The feedwater is heated to the maximum permissible extent in a feedwater heater using controlled or uncontrolled extraction from the steam turbine.

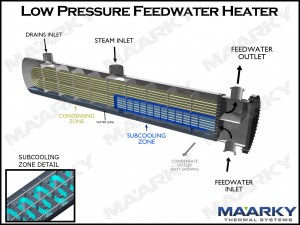

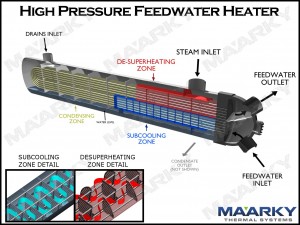

Low Pressure Feedwater Heater High Pressure Feedwater Heater

Maarky provides high, intermediate and low pressure feedwater heaters to the power industry for steam turbine applications ranging from 10 MW – 1,000 MW. The heaters can be designed for a variety of configurations including, but not limited to:

- Horizontal or vertical

- Channel up or channel down

- One, two or three zone

- Duplex

- Channel closure: hemi head, pressure seal or welded diaphragm-bolted cover

Channel up and channel down heaters pose unique design challenges. The number of tubes and the lengths of the desuperheating and subcooling zones are carefully established to enable all zones to perform satisfactorily and to eliminate problems with misdirected flows.

The shell internals are equipped with adequate clearances to ensure proper distribution of steam throughout the entire length of the heater. The number of support plates and baffle plates is calculated such that steam velocities in the heater shell during normal and transient conditions are within acceptable limits and flow induced vibration is avoided.

The shell internals are equipped with adequate clearances to ensure proper distribution of steam throughout the entire length of the heater. The number of support plates and baffle plates is calculated such that steam velocities in the heater shell during normal and transient conditions are within acceptable limits and flow induced vibration is avoided.

Three zone feedwater heaters are equipped with a high efficiency desuperheating-zone. The cross-flow velocity is optimized to offer the highest heat transfer coefficient, minimal shellside pressure drop and zero incidence of flow-induced vibration. The subcooling zone is designed to offer the highest heat transfer coefficient, lowest shellside pressure drop and to eliminate condensate reheating and flashing.